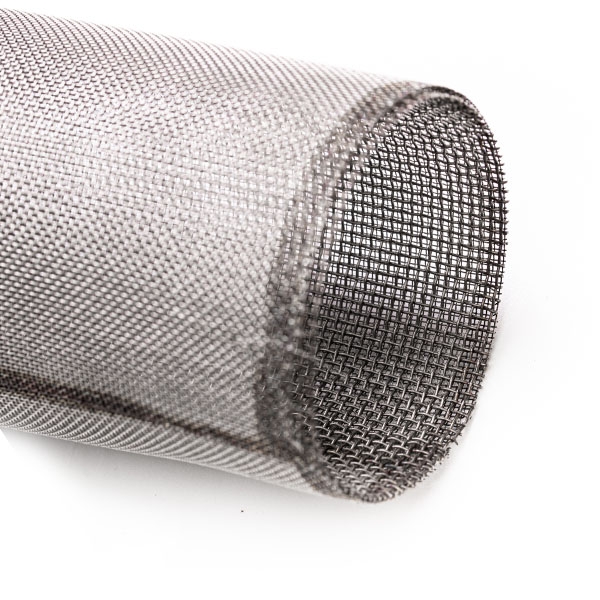

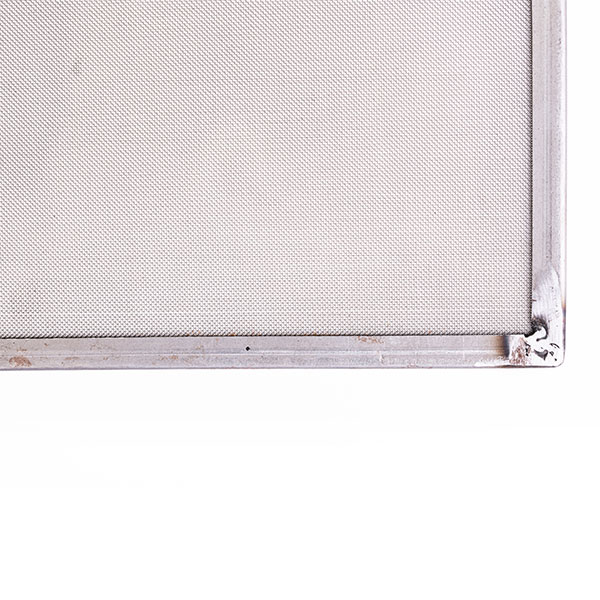

The weaving wire mesh of Tacchi s.r.l. are produced with extreme quality and precision. They are used for multiple solutions: sieving, filtration, shielding, etc. Some of the most important characteristics of wire mesh are stability, resistance over time, resistance to high pressures and temperatures. Furthermore, knowing in depth the characteristics of the wire mesh, it has different solutions in the construction of finished products.

Tacchi metallic wire cloths knowing in depth the characteristics of wire cloths, it has different solutions for every problem. Strongly brought to customization, we can make components according to the customer’s design using wire mesh and offering various types of processing.

The sectors where our finished products are used range a lot, ranging from the automotive sector for the inlet filtration of air, oil and fuel and at the outlet such as exhausts to the appliance sector, where the need to use more and more liquids cleaned requires filters in the process of cleaning them.

Types of processing

Metallic wire mesh in circular and elliptical formats using punch and die molds or in square and rectangular formats using cutter and guillotine.

Curvature of the metallic wire mesh by means of rollers to obtain semi – cylindrical or cylindrical products.

Realization of deep-drawn filters according to the customer’s design through the use of punch and die.

Ultrasonic cleaning systems clean the product ensuring the best degree of cleaning. On request, electro-polishing can be carried out for a higher brilliance.

Used mainly in the architecture sector, we can offer:

– powder coating: carried out in ovens, which due to the electrostatic effect, the metal meshes are covered with synthetic resins and stabilized due to the temperature;

– electro-coloring: the coloring of the wire cloth is obtained by means of an electro-coloring system.

The formation of the different colors takes place by interference, that is, taking advantage of the phase difference existing between the rays reflected by the various oxide surfaces formed during the treatment and those reflected by the surface of the underlying metal.

From initial spool, we can obtain customer-specific height. Based on the customer’s request and the type of wire mesh we can obtain strips with a height starting from about 6.5 mm. We can also combine different heights on the same type of wire mesh to avoid possible scraps and additional costs.

Furthermore, we can already obtain strips from the frame with the possibility of having folded edges as a side finish.

We carry out spot welding to join layers of wire cloth in order to obtain filtering elements according to the customer’s design and request. These so-called multilayer elements can be of different shapes, cylindrical, oval, elliptical, square, rectangular etc.

Reduction of the elastic return of the material by using controlled pressure ovens to avoid oxidation of the material. This treatment is mainly used before carrying out other additional processes to obtain a softer canvas, excluding any stress due to cold weaving.