The products manufactured by the industry sector Heels Weaving Wire Mesh are used in hydraulic filters, vacuum filters and filters source, in caps, in building components, the gates and fence tubing, furniture components.

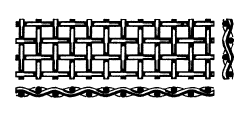

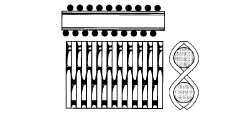

In contrast to the metallic meshes, which are realized with metallic shaped and preprinted wires, metallic cloths are produced with automatic mechanic looms and allow to obtain a grid formed by continuous warp yarns and weft yarns.

DISCOVER OUR PRODUCTS

DEFINITION

By metallic wire cloth is meant the product obtained trough the weaving of continuous metallic wires on automatic mechanical looms. The result is a trellis-work formed by WARP wires (i.e. those parallel to the length of the cloth) and by WEFT wires (i.e. those parallel to the width of the cloth). The latter may be continuous, forming a cloth with lateral “selvedges”.

By metallic net is meant, instead, the manufactured product obtained through the assembly of non-continuos wires, previously shaped or printed.

DATA FOR THE IDENTIFICATION OF A CLOTH

Indispensable for tenders and orders request are the characteristics that must be provided, listed below:

The metallic cloths can be obtained in all metals and alloys which can be drawn.

We include a list of those, most commonly used, their chemical composition and some of their physical properties.

Weight of various materials compared to plain steel that has a specific weight of 7,85

Multiplier coefficient:

- Aluminium 0,328

- Bronze 1,13

- Copper 1,13

- Bras 1,12

- Alpaca 1,104

- Monel 1,141

- Silver 1,35

- Tin 0,935

- Inconel 1,084

- Nichel 1,141

- Nylon 0,145

- Polyester 0,175

Chemical composition

| C | 0.12 max |

| Mn | 1.00 max |

| Si | 1.00 max |

| P | 0.04 max |

| S | 0.03 max |

| C | 14 ÷ 18 |

-

Specific weight 7.75 kg/dm³ at 20°C

-

Specific heat 0.152 Kcal/kg/°C at 100°C

-

Magnetic properties Ferromagnetic

-

Specific resistivity 60 µΩcm at 20°C

Chemical composition

| C | 0.08 ÷ 0.10 |

| Mn | 0.40 ÷ 0.48 |

| P | 0.01 ÷ 0.02 |

| S | 0.03 ÷ 0.04 |

-

Specific weight 7.7 kg/dm³ at 20°C

-

Specific heat 0.118 Kcal/kg/°C at 100°C

-

Magnetic properties Ferromagnetic

Chemical composition

| C | 0.08 max |

| Mn | 2.00 max |

| Si | 1.00 max |

| P | 0.04 max |

| S | 0.03 max |

| Cr | 18 ÷ 20 |

| Ni | 8 ÷ 11 |

-

Specific weight 7.93 kg/dm³ at 20°C

-

Specific heat 0.120 Kcal/kg/°C at 100°C

-

Magnetic properties Not magnetic

-

Specific resistivity 72 µΩcm at 20°C

Chemical composition

| C | 0.08 max |

| Mn | 1.00 max |

| Si | 1.00 max |

| P | 0.04 max |

| S | 0.03 max |

| Cr | 11,5 ÷ 13,5 |

| Ni | 0.06 |

-

Specific weight 7.75 kg/dm³ at 20°C

-

Specific heat 0.152 Kcal/kg/°C at 100°C

-

Magnetic properties Ferromagnetic

-

Specific resistivity 60 µΩcm at 20°C

Chemical composition

| C | 0.08 max |

| Mn | 2.00 max |

| Si | 1.00 max |

| P | 0.04 max |

| S | 0.03 max |

| Cr | 16 ÷ 18 |

| Ni | 10 ÷ 14 |

| Mo | 2 ÷ 3 |

-

Specific weight 7.98 kg/dm³ at 20°C

-

Specific heat 0.118 Kcal/kg/°C at 100°C

-

Magnetic properties Not magnetic

-

Specific resistivity 74 µΩcm at 20°C

Chemical composition

| C | 0.03 max |

| Mn | 2.00 max |

| Si | 1.00 max |

| P | 0.045 max |

| S | 0.03 max |

| Cr | 18 ÷ 20 |

| Ni | 8 ÷ 12 |

-

Specific weight 7.93 kg/dm³ at 20°C

-

Specific heat 0.120 Kcal/kg/°C at 100°C

-

Magnetic properties Not magnetic

-

Specific resistivity 72 µΩcm at 20°C

Chemical composition

| C | 0.03 max |

| Mn | 2.00 max |

| Si | 1.00 max |

| P | 0.04 max |

| S | 0.03 max |

| Cr | 16 ÷ 18 |

| Ni | 10 ÷ 14 |

| Mo | 2 ÷ 3 |

-

Specific weight 7.98 kg/dm³ at 20°C

-

Specific heat 0.118 Kcal/kg/°C at 100°C

-

Magnetic properties Not magnetic

-

Specific resistivity 74 µΩcm at 20°C

Chemical composition

| C | 0.25 max |

| Mn | 2.00 max |

| Si | 1.50 max |

| P | 0.04 max |

| S | 0.03 max |

| Cr | 24 ÷ 26 |

| Ni | 19 ÷ 22 |

-

Specific weight 7.98 kg/dm³ at 20°C

-

Specific heat 0.118 Kcal/kg/°C at 100°C

-

Magnetic properties Not magnetic

-

Specific resistivity 90 µΩcm at 20°C

Chemical composition

| C | 0.08 max |

| Mn | 2.00 max |

| Si | 1.00 max |

| P | 0.04 max |

| S | 0.03 max |

| Cr | 17 ÷ 19 |

| Ni | 8 ÷ 11 |

| Ti | 5xC min |

-

Specific weight 8.02 kg/dm³ at 20°C

-

Specific heat 0.118 Kcal/kg/°C at 100°C

-

Magnetic properties Not magnetic

-

Specific resistivity 72 µΩcm at 20°C

Chemical composition

| Ni | difference at 100 |

| C | 0.10 max |

| Mn | 0.50 max |

| Fe | 5 max |

| S | 0.0015 max |

| Si | 0.50 max |

| Cu | 0.10 max |

| Cr | 20 ÷ 23 |

| Cr+Ta | 3.15 ÷ 4.15 |

| Mo | 8 ÷ 10 |

| AI | 0.40 |

| Ti | 0.40 |

-

Specific weight 8.44 kg/dm³ at 20°C

-

Specific heat 0.098 Kcal/kg/°C at 100°C

-

Magnetic properties Ferromagnetic

-

Specific resistivity 99 µΩcm at 20°C

Chemical composition

| Ni | 63 ÷ 70 |

| Fe | 2.50 max |

| Mn | 1.25 max |

| C | 0.30 max |

| Si | 0.50 max |

| S | 0.024 max |

| Cu | difference at 100 |

-

Specific weight 8.84 kg/dm³ at 20°C

-

Specific heat 0.127 Kcal/kg/°C at 20°C

-

Magnetic properties Slightly ferromagnetic

-

Specific resistivity 48.2 µΩcm at 20°C

-

Curie point 60°C

Chemical composition

| Cu+Ag | 99.9 max |

| Pb | 0.005 max |

| As+Bi+Ni | 0.10 max |

-

Specific weight 8.90 kg/dm³ at 20°C

-

Specific heat 0.092 Kcal/kg/°C at 20°C

-

Specific resistivity 1.71 µΩcm at 20°C

Chemical composition

| Cu | difference at 100 |

| Sn | 6 ÷ 8 |

| P | 0.03 max |

| Pb | 0.05 max |

| Fe | 0.10 max |

| Zn | 0.20 max |

| Sb | 0.01 max |

-

Specific weight 8.80 kg/dm³ at 20°C

-

Specific heat 0.09 Kcal/kg/°C at 20°C

-

Specific resistivity 13 µΩcm at 20°C

Chemical composition

| Cu | 66 ÷ 68 |

| Pb | 0.20 max |

| Fe | 0.15 max |

| Al | 0.05 max |

| Sn | 0.20 max |

| Si | 0.15 max |

| Mn | 0.10 max |

| Ni | 0.30 max |

| Zn | difference at 100 |

-

Specific weight 8.5 kg/dm³ at 20°C

-

Specific heat 0.09 Kcal/kg/°C at 20°C

-

Specific resistivity 6.63 µΩcm at 20°C

Chemical composition

| Al | 99.5 max |

| Fe | 0.20 max |

| Si | 0.10 max |

| Zn | 0.04 max |

| Cu | 0.005 max |

| Ti | 0.006 max |

-

Specific weight 2.72 kg/dm³ at 20°C

-

Specific heat 0.226 Kcal/kg/°C at 100°C

-

Specific resistivity 2.82 µΩcm at 20°C

Our equipment allows you to build metallic wire cloths of variable heights, depending on the type, from 4 mm to 3260 mm. In our stock are available standard sizes of 1000, 1300, 1600 and 2000 mm.

Normally metallic wire cloths is supplied in rolls of variable length according to the type and end use; the length can vary from 25 meters to 100 meters and more, according to the weight of the canvas and the customer’s needs.

Each wire cloth is defined by the NUMBER of meshes (free opening + 2 half wires) in a given unit of measure. The most important numerations are:

FRENCH NUMERATION (N.P.F.) n° of meshes counted in a metric inch of mm 27,77

ENGLISH NUMERATION (Mesh) n° of meshes counted in a linear English inch of mm 25,40

Also used in Italy:

ITALIAN NUMERATION (NIT) n° of meshes in 50 linear mm

WE ADOPT THE FRENCH NUMERATION

We can supply wire cloth with threads from 0.025 mm up to 2 mm in diameter, based on the material, filtration and type of fabric required.

The metallic cloths are different both for the size of the cloth and for the diameter of the wire used for the weaving, for the number of meshes and for the type of weaving, which can form a plain, twilled woven, twilled woven barbed, plain Dutch twilled, Dutch twilled weave and pz.:

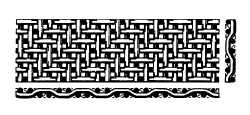

The warp and weft wires intersect alternatively one below and one above the other. The meshes have wires that form perfect 90°right angles and so obtain the maximum light regularity. This is the most commonly used cloth mesh and is found in a wide range of applications.

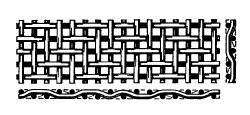

The warp and weft wires intersect alternatively two below and two above. In this weaving the wires tend to form different 90°right angles as a result of non compensated tensions. This is generally used for very mesh cloths, more than 220 in number, or when it is necessary to use larger diameter wires as regards the mesh opening. In this case the wire is subject to less enervation yield thanks to a greater bending radius.

In order to limit, at least to same extent, the problem of mesh irregularity and to avoid the risk of the texture not remaining “in square”, there is inversion, at regular intervals on the width, of the direction of the intersection of the wires with regard to the width itself. In this way, there is tension compensation and thus there is no warping of the cloth.

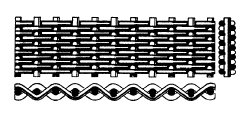

The intersection of the wires, where the warp diameter is larger than the weft diameter, follows the system of“plain” cloth, but the weft wires match. In this way, the passage is only transversal and occurs in the interstices formed at the intersection of the wires themselves.

In this case, too, the weft wires match, but the intersection of the wires occurs according to the “twilled” system. In that case, compared to the “Reps” wires, given the same Ø of wire, a greater number of wires can be used, thus obtaining more thickness. Both“Touraille” and“Reps” are widely used in those filters where there is heavy operation pressure.

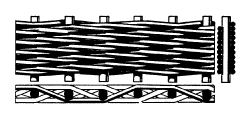

This cloth is a variant of type Reps and aims at maximum filtering capacity, which is obtained thanks to an elevated passage surface. By manipulating the warp and weft wires, filtering openings from 10 to 100 microns can be obtined, with a usable crossing surface of 30-40%, maximum yield for similar performance.

The weft threads are larger in diameter than the warp threads in a similar way to the PZ fabric. The weft threads are in cross weave. In this way the warp yarns are not highly stressed, so the fabric lends itself well in applications with strong mechanical stresses. The particularity of the fabric finds excellent use in the continuous filters of plastic materials, the so-called autoscreen.